Calphalon Cheese Grater

Project goals

This was a sponsored project by Calphalon. The intended output was a cheese grater concept for the 'goddess', a user profile provided by Calphalon.

This project spanned 12 weeks. The research phase was a group effort with Stephanie Ciccolini and Lucas Barrie, the design phase was solo effort. Calphalon funded and supervised this project.

Research

I identified the 'Goddess' as being someone in their late twenties to early sixties. The like the entertain and care about their image and direct their image my purchasing name brand goods. They generally like to showoff their good and ability to cook. I then looked at market analysis and found that Cooks Illustrated has released an in-depth review of the current cheese graters. I used this information to test the 'best' cheese graters with users.

By testing the different cheese graters with different users I was able to see exactly how they use the products, from the initial attempt to use the affordances to build a mental model, to cleaning. I was able to distill the insights into three design requirements, easy to use, grated cheese containment and cheese type versatility.

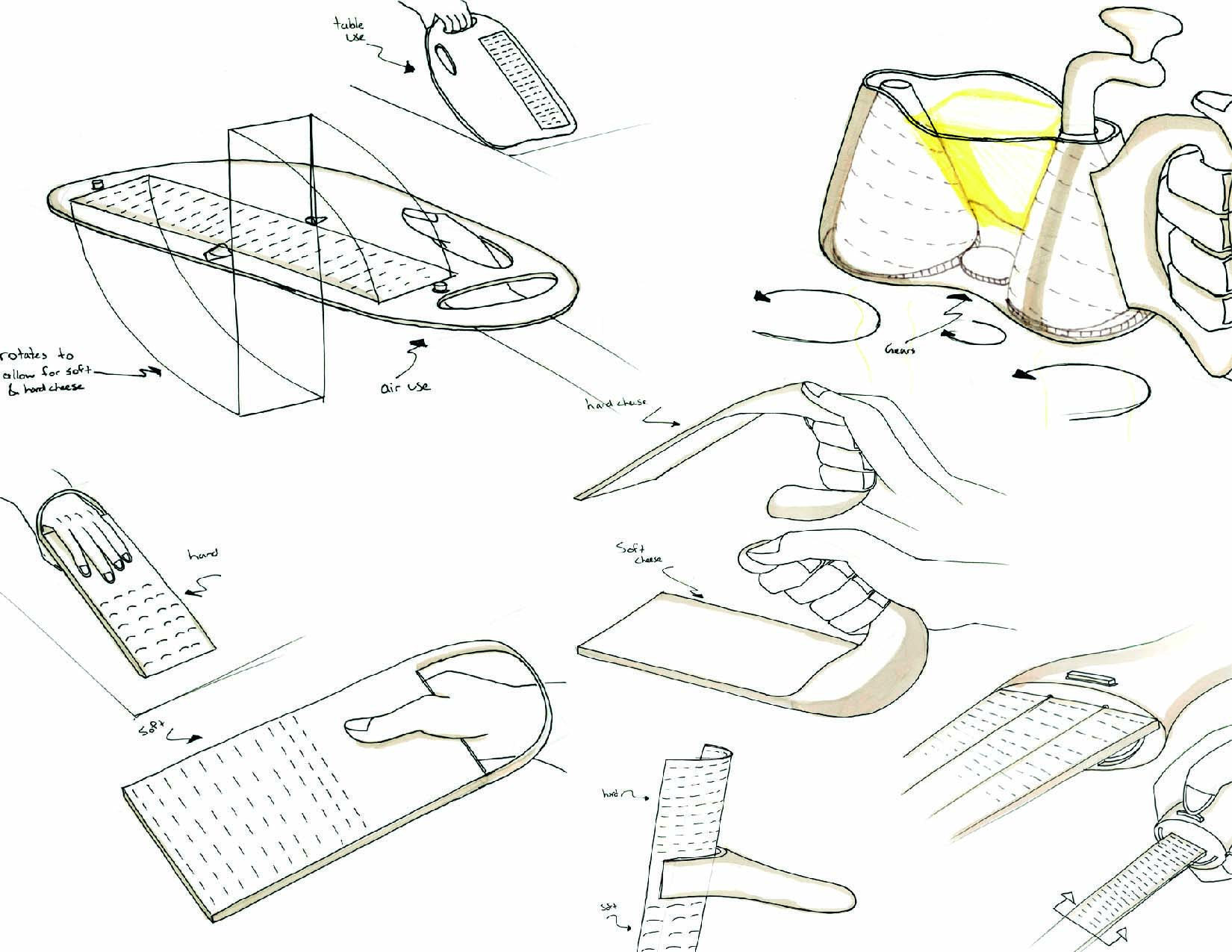

Ideation

I sketches to explore different concepts. From my research I knew that users want the ability to use hard and soft cheeses, control where the grated cheese goes and something thats comfortable.

Using a standard sheet metal, I made my own grating surface. I would drill two different size hole alternating in rows. By extruding one edge of the hole I could create a grating surface and by repeating that on both sides of the metal, I made a dual grating surface out of one piece of metal.

As I refined the concept I sketched and build many foam models to perfect the form.

Working with paper and foam I was able to continuously test the forms for comfort. I incorporated a ball joint in into the form to allow the dual grating surface to rotate freely.

Concept

The final model was made with vacuum forming a foam model, milling a wax block to cast the ball joint and laser cutting the grating surface.

The 3d models where build in Rhino and rendered in Keyshot. I was awarded the Best Overall Concept by Calphalon.